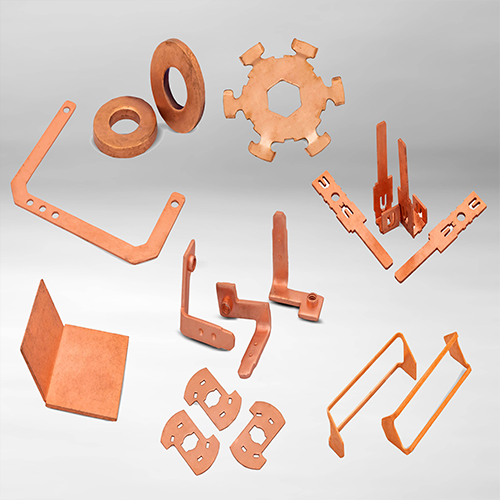

Copper Electroplating

At Shree Sainath Electrocote Pvt. Ltd., we provide superior copper electroplating services, leveraging copper’s excellent conductivity, malleability, and corrosion resistance. Copper is an ideal choice for coating components across various industries, including aerospace, automotive, electronics, and telecommunications.

Key Benefits of Copper Electroplating :

Enhanced Conductivity : Copper is one of the best conductors of electricity, making it an ideal choice for improving the electrical performance of components used in electronic devices, wiring, and connectors.

Malleability : Copper’s high malleability makes it perfect for parts that require flexibility and the ability to withstand bending or reshaping without breaking.

Corrosion Resistance : Copper plating offers excellent protection against corrosion, extending the lifespan of components exposed to harsh environments or high-stress conditions.

Cost-Effective : Copper electroplating is a cost-efficient process, providing high-quality surface finishes at a competitive price point.

Copper Electroplating Methods :

Electroplating : In this process, metal substrates are immersed in an electrolytic bath, and an electric current is used to deposit copper ions onto the surface, creating a thin, uniform copper coating.

Barrel Plating : This method is ideal for plating a large volume of smaller parts simultaneously. Our custom-designed barrel plating equipment ensures efficient and consistent results, delivering high-quality finishes across all components

Rack Electroplating : For more complex or delicate parts with strict plating specifications and testing requirements, rack electroplating offers precise control. We accommodate both prototype and mass production volumes, ensuring all components meet exacting standards. Copper electroplating offers a unique combination of properties, making it an excellent choice for enhancing the performance and durability of various metal substrates. Whether you need improved conductivity, flexibility, or corrosion resistance, our copper plating services are designed to meet your exact specifications.