28

Years

Experience

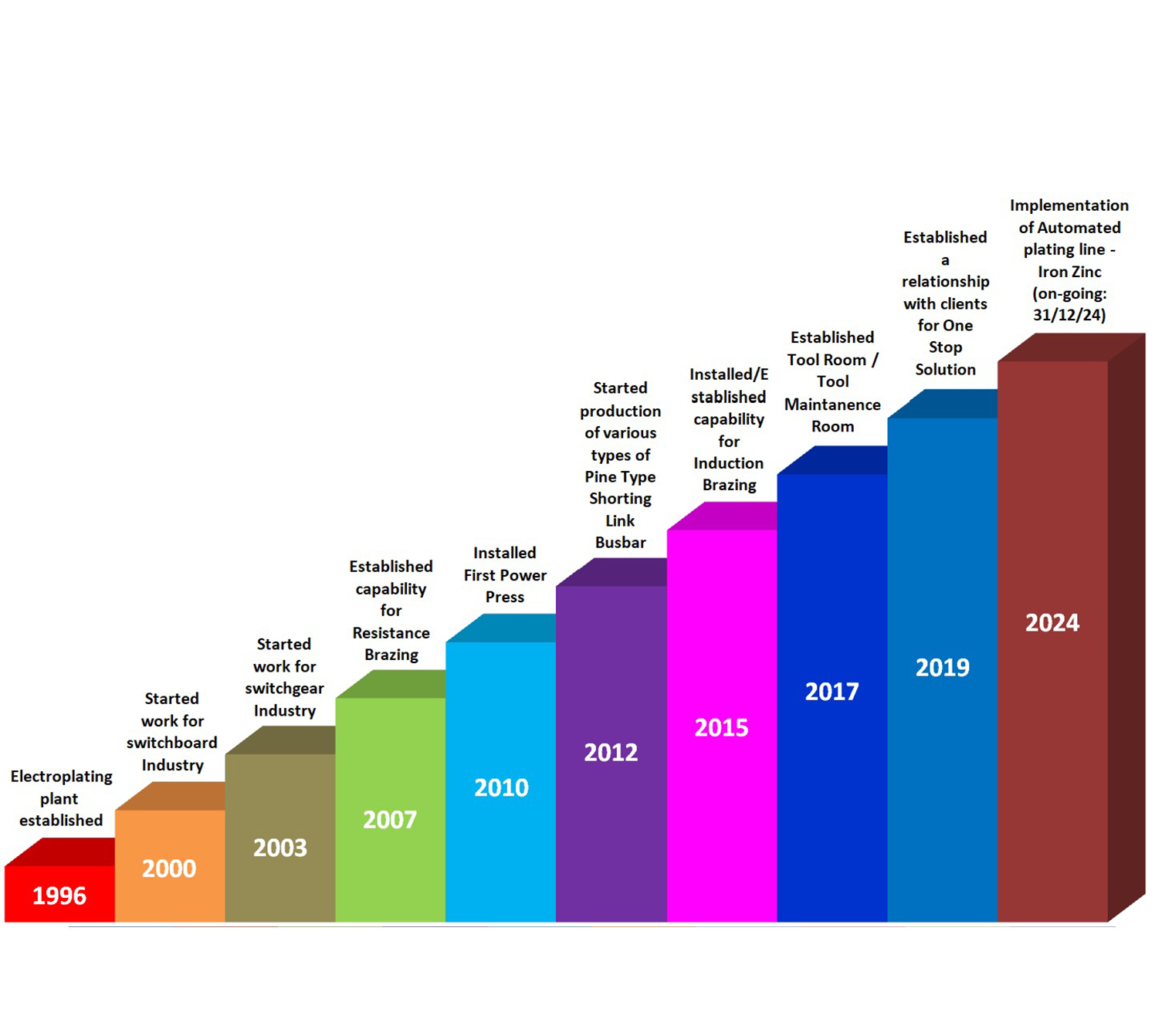

We’re recognized as leader and innovator in the plating business, as well as manufacturer of mechanical and electrical components.

Since inspection in 1996, Shree Sainath Electrocote Pvt. Ltd. has built a strong reputation for providing high-quality surface treatment and precision stamping solution

Resistance and Induction Brazing

Surface Treatment Solutions

Precision Stamping Solutions

Shorting Link Busbar Manufacturer

Busbar Manufacturer

Call Us:+91 9769769629 / +91 7718845161

Shree Sainath Electrocote Pvt. Ltd. is a recognized leader and innovator in the plating business, as well as a well-established manufacturer and supplier of a comprehensive range of electrical and mechanical components. Since its inception in 1996, the company has built a strong reputation for providing high-quality surface treatment solutions.

Services offered include:

- Surface Treatment Solutions: Iron-zinc coating

- Resistance and Induction Brazing

- Manufacturing of Sheet Metal Components

Zinc coating

Copper plating

Silver plating

Tin plating

Plating on aluminum components

CED coated components

Shree Sainath Electrocote Pvt. Ltd. is committed to quality, strictly adhering to industry norms and guidelines. By using top-grade raw materials and advanced machinery, the company ensures that its products are known for sturdiness, durability, dimensional accuracy, and resistance to corrosion, making them a preferred choice in the market. Additionally, the company offers electroplating services at competitive rates, further solidifying its market presence.

Operating out of a state-of-the-art infrastructure, the company is equipped with all necessary machinery and equipment to efficiently achieve its goals and objectives. The facility is organized into several operational units, each contributing to the company’s high productivity. Shree Sainath Electrocote Pvt. Ltd. is also known for its ethical work practices, which have helped attract and retain many highly reputed clients. Regular facility upgrades ensure that the company maintains its competitive edge in the market.